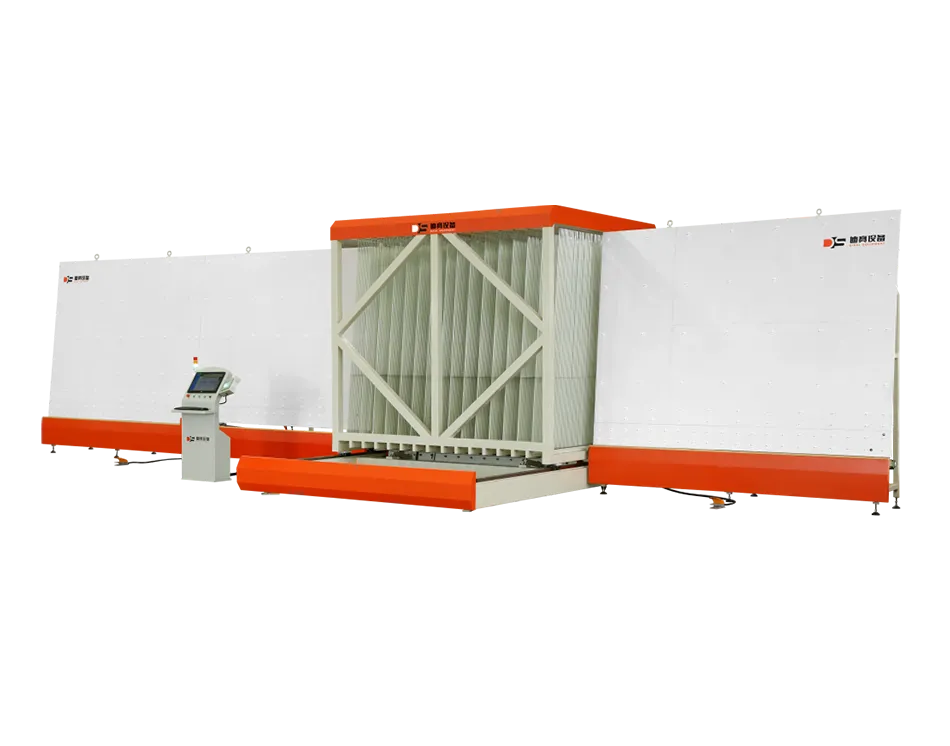

Composition Vertical transfer platform(manual/auto loading)+vertical detection bench + mobile net rack +vertical transfer platform (manual/auto unloading)

Composition Vertical transfer platform(manual/auto loading)+vertical detection bench + mobile net rack +vertical transfer platform (manual/auto unloading)

1、Put the scattering glasses into path; fast and precise inspection and system intelligent comparision and optimization; receive films based on the rack mode.

2、Replacing artificial film matching and label pasting and removing to improve production efficiency.

3、Supporting work ticket scanning and reading ERP date for comparison.

4、It is directly connected when film is sorted with single rack and the upper glass is also the lower one; it will not be saved in net grid; continuous film sending allowed.

|

Category |

Parameters |

|

|

Thickness of Processed Glass |

3-8mm |

|

|

Min. Glass Size |

400*400mm |

|

|

Max. Glass Size |

2500*2000mm |

|

|

Glass Delivery Speed |

45m/min |

|

|

Net Rack Moving Speed |

10m/min |

|

|

Connecting Power |

10kW |

|

Category |

Parameters |

|

Workbench Platform |

550土20mm |

|

Mobile Net Rack Path |

60 |

|

Number of Connected Hollow Glass Pairs |

30 |

|

Number of Single Rack Glass Pieces |

60 |

|

Average Glass Piece Efficiency |

4 pcs/min |

Pairing mode

Applicable to online use prior to insulating glass line;send different glasses in need of repairing for two racks into rack sorting system; the pieces will be sent out after well repaired based on the sequence in work ticket in order;

Sequence mode

Applicable to offline prior to insulating glass; send different glasses in need of repairing of single rack to rack sorting system;the pieces will be sent out based on sequence in work ticket.

Efficiency mode

Applicable to offline use prior to edge grinding or glazing; send out pieces based on the whole small batch of orders and size; the scattering ones will be integrated to reduce the edge grinding times; the edge grinding efficiency can be 1-3 times higher than previously.